PALLETIZING

PRODUCTION SUPERVISION

Suitable supervision software packages ensure full control of the line’s operation and the traceability of output. Programs and palletizing layouts are controlled using off-line programming techniques.

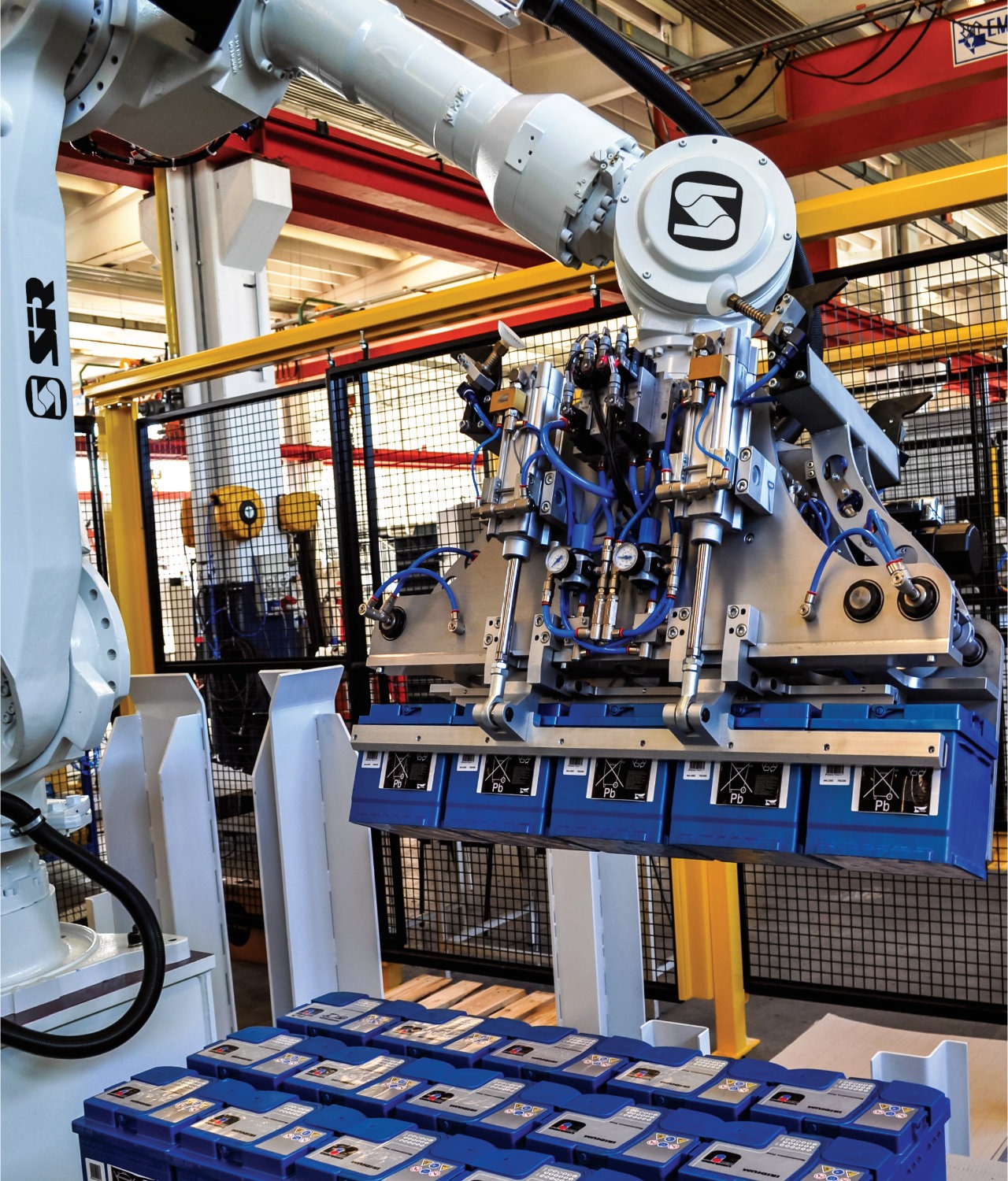

DEDICATED GRIPPERS

SMART LOGISTICS

FUNCTIONAL CHARACTERISTICS

Production supervision

Production traceability

Dedicated grippers

Cutting-edge picking

APPLICATION AREAS

Food and Beverage

Tissues

General Industry

Ceramics and brickware

SOLUTION EXAMPLES

- Beverage industry picking and palletisazion.

- LGV handling and storage of materials and products.

-

Picking and randomised depalletizing.

-

End-of-line automation.

-

Manipulation, handling and preparation of cartons and boxes.

-

Manipulation, handling and preparation of items in general industry.

- Automated Palletisation for Food Industry.

VIDEO

DOWNLOAD THE BROCHURE

To download the complete brochure of SIR Palletizing solutions, enter your data and click “SEND”: you will receive an email with the link to download the PDF file at the address you provided within a few minutes.